If the windlass motor has been changed and the control has been repaired, then there must be a problem with the relay. The relay allows the opening and closing of an electrical power circuit based on logical information. Quick remote control cables - ©ajitecrew Step 3: Checking the relayĪn electromechanical relay is an electrical device that distributes power based on an order issued by the control part. You can hear a little click, but the windlass still doesn't turn! We think that a manual windlass would be easier to repair.

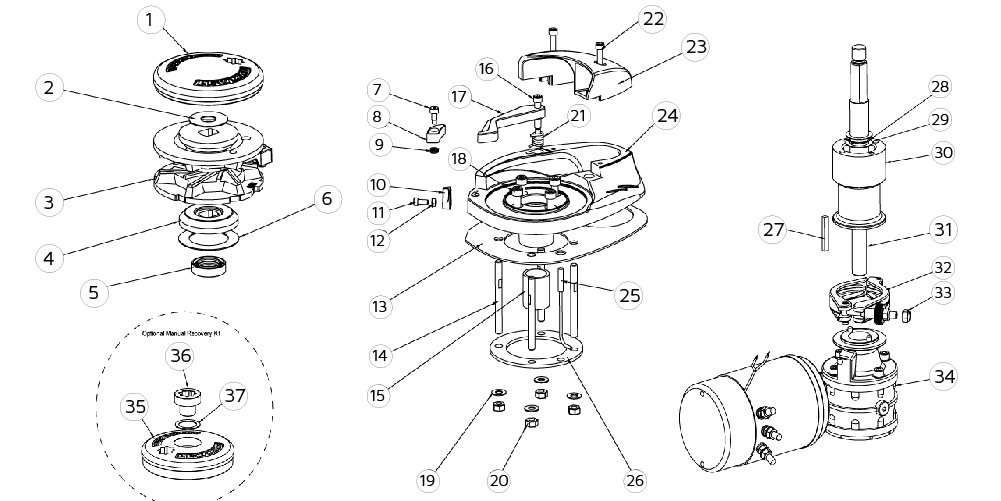

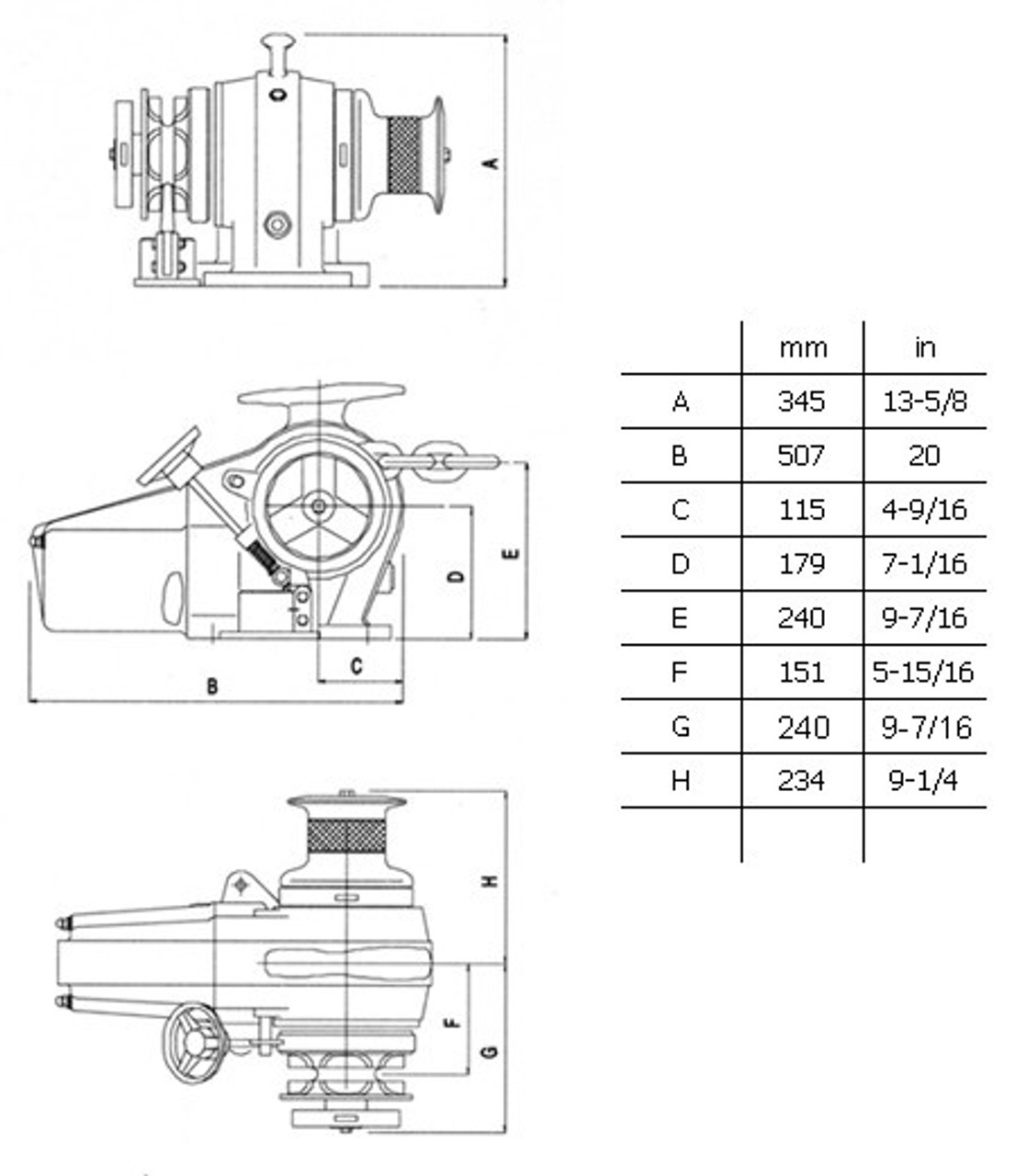

Now that the remote control is fixed, we tell ourselves that now it's ok, it's going to work! It's time to go to the test. Of course, when we take care of the electrical system on the boat, we don't forget to make sure that we have a circuit breaker before touching the cables. We will also use a metal brush to clean the corrosion and considering the state of the plug, we decide to weld the electric cables to it with a metal rod. It is therefore necessary to use specific pliers to strip the 3 wires. Opening the remote control, we discover that the cables are damaged, corrosion has also damaged the connections. We're going to check our two-position Quick remote control (UP to raise the anchor, DOWN to lower it). it doesn't work! Changing the control box Step 2: Checking the windlass control system We turn the power back on, it's time to test the electric windlass, we press the up and down button on our windlass control and. When the engine is changed, we also take the opportunity to change the control box supplied with the windlass engine. When the new engine was installed, it was noticed that the stainless steel threaded rods were too large and that they were in contact with part of the engine. Changing engine electric windlass - ©ajitecrew (NB: it's important to always take a picture before removing everything, it will be much easier to put the right elements in the right place). Windlass motor damaged by corrosion - ©ajitecrew Receipt of our new Lewmar GEARBOX 1800W 12V engine, we unscrew, we reconnect, we disconnect, we reconnect. So we have no choice but to change it completely. Bad news, after 15 years of loyal service, the corrosion has increased, the engine is ruined. Here is a feedback that may help you solve your Electric Windlass problem faster! Step 1: Engine Inspectionįirst we'll take a look at the condition of the windlass engine. Back in port, it's time to examine the windlass. It will take more than an hour to hoist the anchor with the help of a rope and the winches, metre by metre. the electric windlass is no longer responding. As the crew prepares to weigh anchor to return to port. After a month of summer sailing on the Ajité Crew, the last anchorage was one too many for the windlass.

0 kommentar(er)

0 kommentar(er)